This week, I gave my students their final exam for Intro to Supply Chain. One of my colleagues, Daniel Wong, taught me to create multiple tests, so I developed three different exams.

As I composed questions that covered all areas of the supply chain, I wondered just how many of us who have grown up in the industry could answer them. Each business develops its own language and methods of communicating, and this often results in outsiders needing a guide or glossary to interpret its acronyms and definitions.

As a new teacher, I wanted to make sure I was providing a proper balance between the academic and preparing my students for a career. I initially adopted a textbook to utilize its outline, and from there developed lesson plans using Harvard Business School (HBS) case studies as a supplement to provide a practical perspective to my lessons.

As anyone who teaches will agree, textbooks can be rather dry. This made it difficult to teach, and hard for the students to understand. While I fully appreciate grasping the theory of how a forecast is built, I also know that when these young people go to work for a company their employer will teach them the intricacies of how the forecasting software works.

As the quarter progressed, the class and I depended less and less on the textbook and more on the HBS cases, as well as on my own expertise and work experience. The case studies we used were topical for the lectures, and included:

- APPLE INC.: Managing a Global Supply Chain

Fraser P. Johnson; Ken Mark

Publication Date: May 16, 2014

Discipline: Strategy - Staple Yourself to an Order

Benson P. Shapiro; V. Kasturi Rangan; John J. Sviokla

Publication Date: July 1, 2004

Discipline: Operations Management - Supply Chain Finance at Procter & Gamble

Benjamin C. Esty; E. Scott Mayfield; David Lane

Publication Date: May 27, 2016

Discipline: Finance

- MOD IV PRODUCT DEVELOPMENT TEAM

Anne Donnellon; Joshua D. Margolis

Publication Date: September 4, 1990

Discipline: Organizational Behavior - Nissan: Recovering Supply Chain Operations

Shikha Aggarwal; Manoj Kumar Srivastava

Publication Date: May 30, 2016

Discipline: Operations Management

Anyone from Honeywell should take a few minutes and read the MOD IV case. I arrived there around 12 years after the case study was written, but found exactly the same conditions in 2002 as had been detailed from 1990: absolutely nothing had changed except the names. It was great! I had the students make their presentations, then gave them the reality. It was a great opportunity to illustrate how corporate cultures truly work.

As I became more comfortable in the classroom I began to introduce my own case studies into the mix. We studied how to manage subjects like Brazilian trade management; the eruption of the Icelandic volcano Eyjafjallajokull; the U.S. West Coast dock strike; five ways demand can blow up supply; and the supply chain risk of operating in certain countries where drug cartels also operate. All provided real life examples of what they can expect. This made teaching a lot of fun – it was like having a staff meeting about the challenges of running a global business.

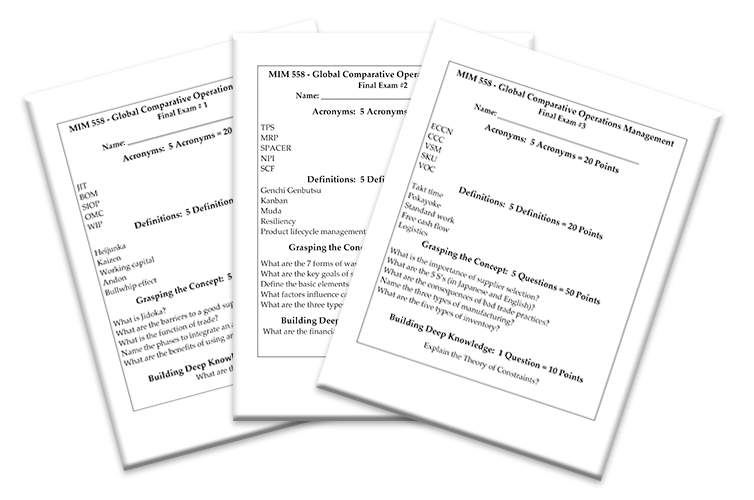

The finals questions were my attempt to include both the academic and practitioner parts of the course. There’s something here for everyone: finance with managing cash and working capital, a heavy dose of TPS, Rhonda Germany’s VOC (What Does Your Customer Want and What Are They Willing to Pay For?) and ‘SPACER’ courtesy of Joe DeSarla. For my Trade friends we weaved the subject matter throughout the questions, along with Goldratt’s Theory of Constraints and SIOP being the fundamental way a business does its planning and manufacturing processes. Mr. Cote, I learned my lessons well.

My colleague Daniel jokingly said that he thought the students would likely “cry when they read it, but go ahead and see what happens.” As it turned out, their scores were truly amazing. The student who was quickest to complete the exam did so in an hour, and the student who took the longest needed two hours.

To that end, I’m not sure whether I’m a really good teacher or if my students simply memorized what I’d taught them — but in the end I achieved my personal goal of delivering the industry a new batch of analysts/ specialists who are business ready and have global experience.

So now my challenge to you is this: Could you pass my final?

MIM 558 – Global Comparative Operations Management:

Final Exam # 1

Acronyms: 5 Acronyms = 20 Points

- JIT

- BOM

- SIOP

- OMC

- WIP

Definitions: 5 Definitions = 20 Points

- Heijunka

- Kaizen

- Working capital

- Andon

- Bullwhip effect

Grasping the Concept: 5 Questions = 50 Points

- What is Jidoka?

- What are the barriers to a good supplier relationship?

- What is the function of trade?

- Name the phases to integrate an acquisition?

- What are the benefits of using an MRP system?

Building Deep Knowledge: 1 Question = 10 Points

- What are the ten steps of OMC?

MIM 558 – Global Comparative Operations Management:

Final Exam #2

Acronyms: 5 Acronyms = 20 Points

- TPS

- MRP

- SPACER

- NPI

- SCF

Definitions: 5 Definitions = 20 Points

- Genchi Genbutsu

- Kanban

- Muda

- Resiliency

- Product lifecycle management

Grasping the Concept: 5 Questions = 50 Points

- What are the 7 forms of waste?

- What are the key goals of sourcing?

- Define the basic elements of trade data?

- What factors influence capacity?

- What are the 3 types of manufacturing?

Building Deep Knowledge: 1 Question = 10 Points

- What are the financial measures of an acquisition integration projects worth? Why?

MIM 558 – Global Comparative Operations Management:

Final Exam #3

Acronyms: 5 Acronyms = 20 Points

- ECCN

- CCC

- VSM

- SKU

- VOC

Definitions: 5 Definitions = 20 Points

- Takt time

- Pokayoke

- Standard work

- Free cash flow

- Logistics

Grasping the Concept: 5 Questions = 50 Points

- What is the importance of supplier selection?

- What are the 5 S’s (in Japanese and English)?

- What are the consequences of bad trade practices?

- Name the 3 types of manufacturing?

- What are the 5 types of inventory?

Building Deep Knowledge: 1 Question = 10 Points

- Explain the Theory of Constraints?

Closing Thoughts

I think that at least a part of why I took to teaching was the result of a trip I once made to deliver a boss from Torrance, California to a bungalow on Augusta National. On that journey I had the opportunity to travel with one of those “Gods of Toyota” I wrote about in another post. He instructed me that it was “incumbent upon me to pass along the knowledge they had taught me to the next generation.” I can honestly say that – since that time – those work instructions have rung in my ears. It was with those altruistic thoughts that I entered the teaching profession.

As I made my way through 12 weeks of readings, lessons and case studies, I worked to keep things simple via teaching People, Process, Tools.

However, I believe it was in Week 4, when my students were learning demand planning and forecasting, that I stopped in the midst of my lecture, looked at the students and said, “You guys really don’t understand a thing I’m saying – do you?” The resounding reply was “No.”

That was when I had a great epiphany: I needed to grab the classic Beer Game to help me teach supply and demand. From there I introduced more case studies, along with a new section called “Ask the Experts” where I interviewed friends in the industry, asking them questions provided by my students. This made things much more tangible and interesting for the students to grasp.

Teaching has been rewarding, but I can honestly say that I’ve worked harder over the past 12 weeks than at any time in my previous 40 years – this is hard stuff.