I was once asked by my CEO — literally, in an elevator: “Jay, what is logistics?” My answer was,

“Sir, you put lots of dots on the map. Suppliers, dealers, customers. Our job is to connect those dots in the most efficient, effective manner.”

Logistics is the marriage of the physical movement of material with the flow of cash and information. The process starts with a trigger to move goods, and ends with their final delivery. It includes the flow of raw materials for production, Work in Progress (WIP), and the deliveries of finished goods to customers.

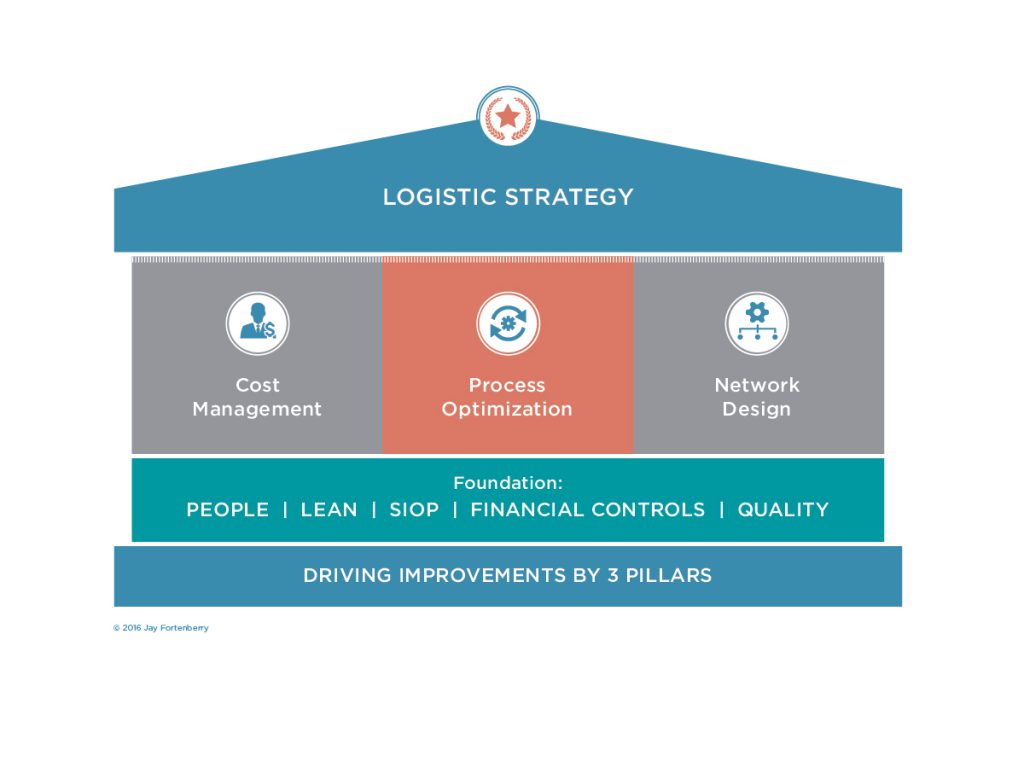

Toyota views the flawless execution of logistics as an integral part of its core values of Just-In-Time. Conversely, many short-sighted companies see logistics as a cost: freight, warehousing and trade. They fail to understand the inherent risk of poor performance or the tremendous opportunities yielded by performing well. Additionally, people often think it’s easy to shave a nickel off of an air freight rate, but fail to understand that it’s also about speed, reliability, quality and reducing the risk of an on time/ defect-free delivery. Historically, I’ve found that successful logistics programs are built upon a foundation of network design, process optimization and cost management.

These three facets work together to provide the basis for how a business’s strategy is actually executed. Furthermore, if these are not executed properly, trade issues prevent crossing borders, cash is lost and the entire enterprise is jeopardized.

The following case study will cover these three areas to illustrate how logistics is tied directly to cash and the Cash to Cash cycle.

Case Study

Project Big Bowl

A side note before I start: The name “Big Bowl” came from eating in an Asian Fusion restaurant outside of Minneapolis one evening. A very dear friend, Mr. Robert Muir, coined the name, and we all thought it was very applicable to the subject at hand.

Building a Distinct Competitive Advantage from Asia to the World

Background:

A crashing economy coupled with mass globalization and increased regulatory requirements for enhanced security made flows from Asia to the U.S. become exceedingly difficult in 2009.

Factory or Supplier

- Factories and suppliers were holding inventory to build full container loads for cost

- Numerous emails were mandatory for shipment status

- Working capital (inventory) abounded, as no one was managing the supply chain

- Visibility of shipments was limited until the container arrived at the plant

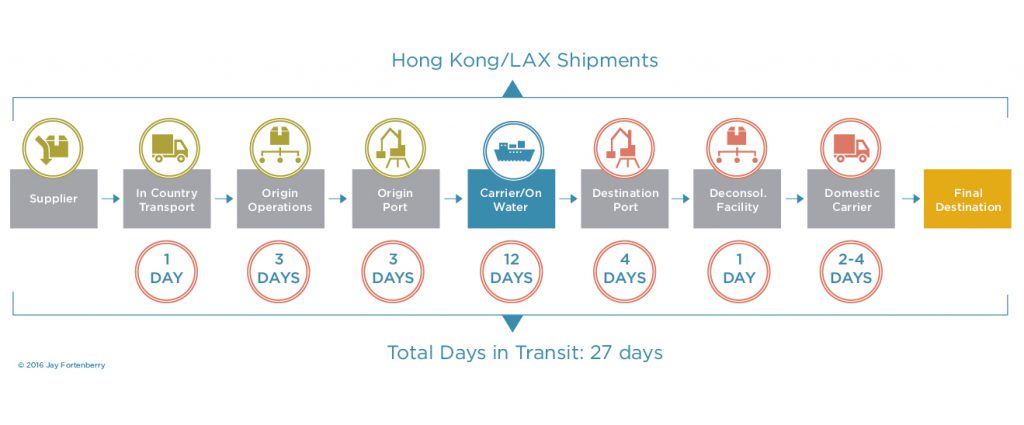

Origin Transport

- Vessel sailings were infrequent. If sailings were missed, a minimum of a week delay would be incurred

- Tracking and tracing did not exist

- Trade compliance was difficult as there was limited data on the multiple filers in each container

Destination Transport

- There was a lack of visibility on the final mile to plants, warehouses and customers

- Rail congestion abounded across North America

- Bond issues with U.S. Customs were the norm for overages and shortages

Other Facts to Note:

- The U.S. implemented an anti-terrorist program called Importer Security Filing (ISF) which required that 12 new data fields be completed 48 hours prior to any shipment departing for the U.S., which we were incapable of providing

- International transportation costs were in a continual state of turmoil from fuel prices, inflation/ deflation, bankruptcies, labor stoppages, regional conflicts and natural disasters

The days of loading containers on the side streets of Hong Kong were over, however we were still routinely doing it.

Project Objectives:

Design one transportation management solution to improve velocity and reduce cost that provided:

- Management of daily flows across all regions and businesses

- Reduction of cycle time through enhanced visibility and management

- Optimization of movement to maximize speed while minimizing costs

- A single point of contact for all shipments

- Compliance with all regulations

- End-to-end visibility and traceability to customers

- Increased flexibility by reduction of handoffs, routing optimization and consolidations

Results:

Big Bowl became a global supply chain management solution that improved velocity and reduced cost. It transformed 97 supply chains in 12 months by coordinating flows and information from sourcing, materials management, plant operations and distribution.

Savings:

- 2011 Working Capital = $4.3M/ Cumulative 2009-2011 = $15.5 million

- No impact from disasters such as the Fukushima earthquake and tsunami

Factory or Supplier

- Created centralized booking via a Control Tower process

- Provided visibility from Booking to Delivery with projected arrival dates

- Validated all documents to ensure customs compliance

- Simplified and delivered a single platform for order status

Origin Transport

- Managed carrier allocation to minimize dwell time at origin ports

- Selected the shortest transit base on all carriers

- Created a single platform for shipment status from scheduled to actual

Destination Transport

- De-consolidated 40’ marine containers to consolidate multiple shipments into 53’ road trailers

- Developed flexibility to expedite and/or defer inventory

- Provided visibility of the Final Mile with actual Proof of Deliveries (POD)

Final Thoughts (for today) on Logistics

Logistics is not for the faint of heart – there is seldom any room for error, and we’re always remembered for the last delivery. Logisticians are expected to make it through any global phenomenon, be it 9/11, a Japanese or California earthquake, or an Icelandic volcano, and we’re supposed to do it seamlessly and invisibly. I’ve studied logistics and led logistics processes for over 40 years, and I still totally love doing it. Logistics fields the ball from the very beginning of the process, then advances it down the field for the ultimate score → cash.